A BIM-Model usually comprises building components such as walls, ceilings, struts, windows, doors, etc. In rare cases also, technical components and equipment.

Especially when it comes to 3D-post-documentations of existing buildings the data collected is limited to the above-mentioned building components due to financial reasons.

Further factual information is vital for documentation, inspection and maintenance processes when utilising 3D-building models. A large part of this information is usually kept within separate data pools and structures. Our aim is to bring all this information onto one data base to guarantee seamless process integrations in the sense of a digital twin!

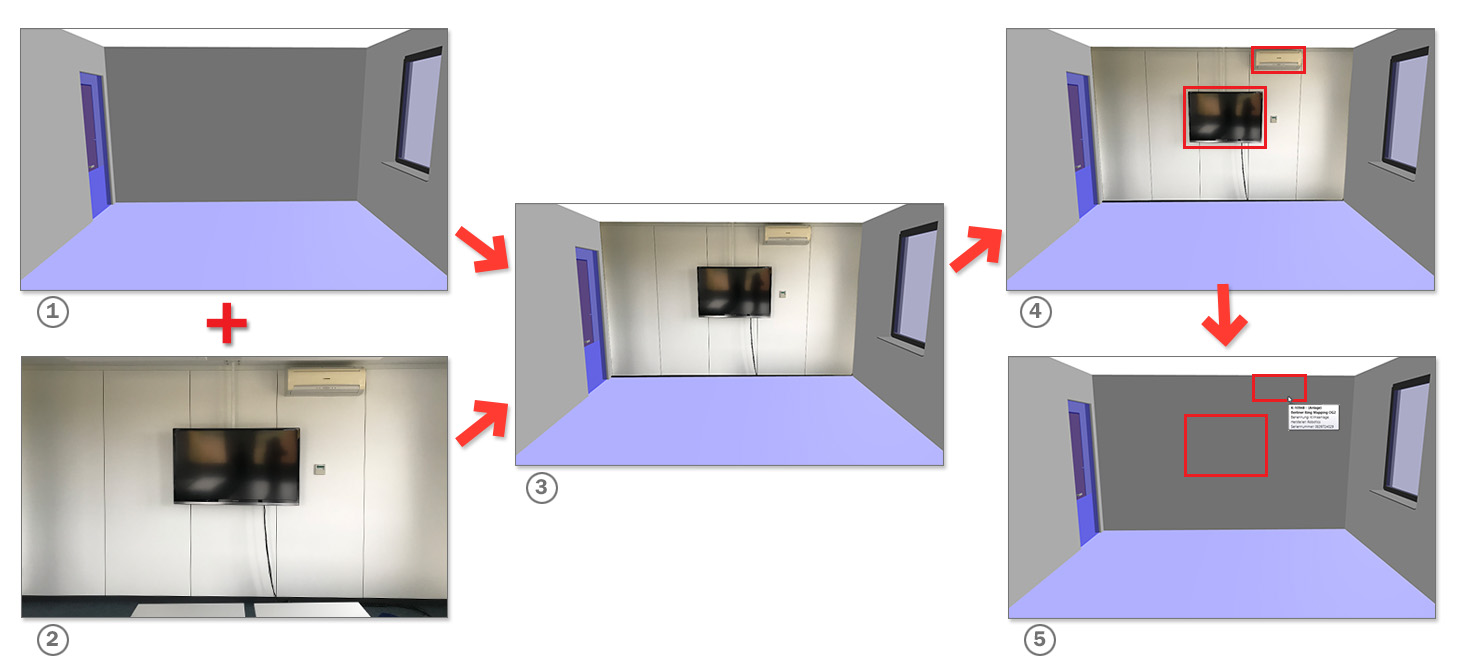

Due to extensive research and development we are able to use modern AI-methods for automatic mapping of photogrammetric documents (e.g. pictures of walls) with BIM-models. From these pictures further details can be extracted. It is possible to identify building components including their factual data and storing this information within the building component data structure. This way a ‘trained’ system can easily identify and document switches, power sockets, heating elements, door and window models, air conditioning systems, etc.

Further existing information can be linked, if building components are distinctively identified.

A logical connection between factual and master data with process data is a core component of our speedikon® C-system. All objects including all their relevant information are accessible by the push of a button. These functions are now rolled out onto photogrammetric documents. This allows a high visualisation of all data and is also more cost-efficient compared to expensive complex 3D-modulations.

The documentation process is also highly relevant within the diverse building stages as a number of situations after covering ceilings, walls and floorings are no longer comprehensible. Of course, documenting building stages photogrammetrically is not new but we go further. We integrate this photo documentation true-to-location including a complete time reference within the 3D-model. Any information is displayable and ready for further processing by the push of a button.